Home >> Product >> Crane Rail

Material: U71Mn

Weight:63.69Kg/m

Length:12m

Standard:YB/T5055-2014

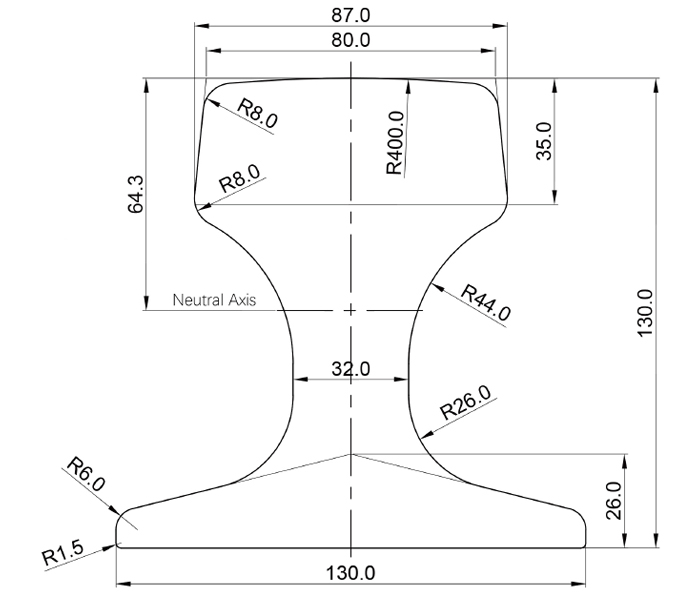

| Parameters | |||

| type | weight (kg/m) | material | length (m) |

| QU80 | 63.69 | U71Mn | 12 |

| rail height (mm) | bottom width (mm) | head width (mm) | web thickness (mm) |

| 130 | 130 | 80(87) | 32 |

| Crane Rail | Size | Rail Height | Bottom Width | Head Width | Web Thickness | Weightkg/m |

| QU70 | 120 | 120 | 70(76.5) | 28 | 52.80 | |

| QU80 | 130 | 130 | 80(87) | 32 | 63.69 | |

| QU100 | 150 | 150 | 100(108) | 38 | 88.96 | |

| QU120 | 170 | 170 | 120(129) | 44 | 118.10 |

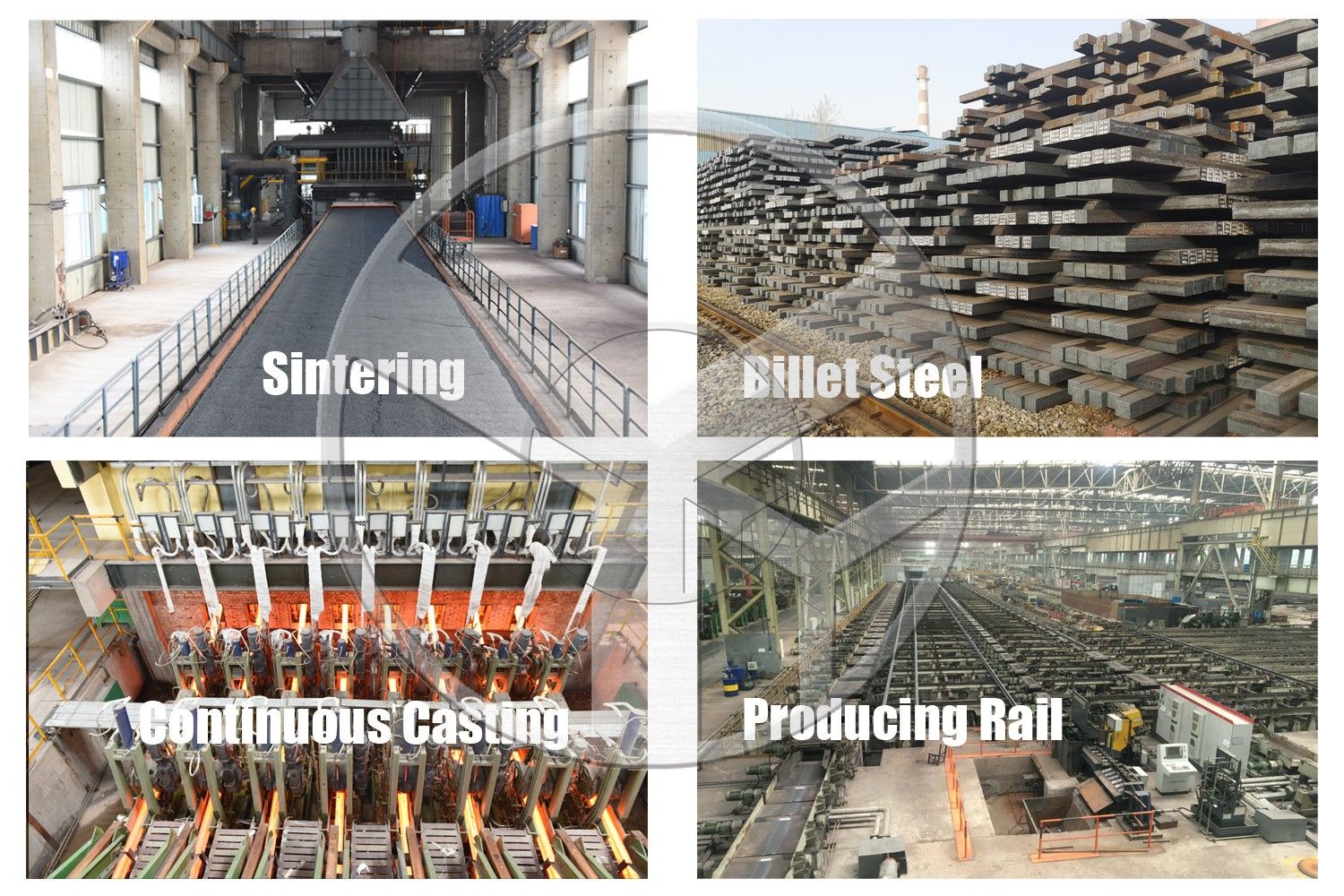

Introducing the Qu80 Rail, a high-performance rail solution designed to meet the rigorous demands of heavy-duty applications. With its exceptional strength, durability, and precision engineering, the Qu80 Rail sets a new standard for excellence in the industry.

The Qu80 Rail is specifically engineered to support heavy machinery and equipment in various industrial sectors. Made from high-quality steel, this rail boasts an impressive load-bearing capacity, ensuring reliable and efficient material handling operations.

One of the key advantages of the Qu80 Rail is its precise design and profile. With carefully calculated dimensions, it offers optimal support and stability for cranes and other heavy machinery, resulting in smooth and precise movement during material handling processes.

Durability is paramount in demanding environments, and the Qu80 Rail delivers on that front. Manufactured using superior materials and advanced production techniques, this rail is built to withstand heavy loads, extreme temperatures, and harsh operating conditions.

The Qu80 Rail is a versatile solution suitable for a range of applications, including ports, construction sites, manufacturing facilities, and more. Its exceptional performance and reliability make it an ideal choice for industries that require efficient and safe material handling operations.

Application:

The Qu80 Rail, renowned for its exceptional strength and durability, finds extensive application in a wide range of heavy-duty operations. Designed to handle demanding industrial environments, this rail solution offers unparalleled performance and efficiency across various sectors.

◆Ports and Harbors: The Qu80 Rail proves indispensable in port and harbor operations. Its robust construction and high load-bearing capacity make it ideal for facilitating the smooth movement of heavy cargo, containers, and cranes, ensuring efficient loading and unloading processes.

◆Steel Mills and Foundries: In steel mills and foundries, where heavy machinery and equipment are in constant motion, the Qu80 Rail excels. It provides a reliable foundation for the safe and precise transport of raw materials, molten metal, and finished products, optimizing workflow and enhancing productivity.

◆Construction Sites: At construction sites, the Qu80 Rail offers unmatched support for heavy machinery like tower cranes and mobile cranes. It ensures stability and precision during material handling, contributing to the safe and efficient completion of construction projects, whether it's lifting heavy loads or transporting equipment.

◆Mining and Quarrying: In the mining and quarrying industry, the Qu80 Rail proves its mettle by facilitating the transportation of massive amounts of materials, including ore, coal, and aggregates. Its durability and load-bearing capacity make it a reliable choice in these demanding environments, ensuring uninterrupted operations.

◆Steel Structures and Bridges: For the construction of steel structures and bridges, the Qu80 Rail plays a crucial role. It provides a stable platform for moving heavy components during assembly, enabling efficient construction processes while maintaining structural integrity and safety.

◆Manufacturing Facilities: In manufacturing facilities, the Qu80 Rail serves as the backbone for material handling systems, supporting the smooth movement of goods, equipment, and machinery. Its precise profile and high-quality construction enhance operational efficiency, contributing to streamlined production processes.

These are just a few examples of the diverse applications where the Qu80 Rail shines. Its versatility, strength, and reliability make it a go-to choice for industries that demand efficient and safe material handling solutions.

Choose the Qu80 Rail for your heavy-duty operations and experience the difference it can make. Contact us today to discuss your specific requirements and discover how our top-of-the-line rail solution can optimize your industrial processes, ensuring success and longevity for your business.

Frequently Asked Questions (FAQ) about Crane Rail:

1. What is a crane rail?

A crane rail is a specially designed rail track used for supporting heavy machinery, such as cranes, in industrial applications. It provides a stable and durable surface for the smooth movement of cranes and facilitates the safe transport of heavy loads.

2. What are the common applications of crane rail?

Crane rails are widely used in various industries, including ports, construction sites, steel mills, manufacturing facilities, and mining operations. They are essential for material handling, cargo loading and unloading, and the movement of heavy machinery.

3. What are the advantages of using crane rail?

Crane rails offer several advantages, including:

◆High load-bearing capacity: They are designed to support heavy loads, making them suitable for demanding industrial environments.

◆Stability and precision: Crane rails provide a stable platform for the precise movement of cranes and heavy machinery, ensuring accurate material handling.

◆Durability: Made from high-quality materials, crane rails are built to withstand harsh operating conditions, reducing maintenance needs and enhancing longevity.

4. How are crane rails installed?

Crane rails are typically installed on a prepared surface using fastening systems like clips or bolts. The installation process may involve leveling, alignment, and securing the rails to the foundation or supporting structure. It is crucial to follow proper installation guidelines and consult experts for optimal results.

5. What factors should be considered when selecting crane rails?

When selecting crane rails, it is important to consider factors such as load capacity requirements, rail profile and dimensions, material grade, operating conditions (e.g., temperature, environmental factors), and specific industry standards or regulations. Consulting with experienced professionals can help ensure the right rail selection for your specific needs.

6. Can crane rails be customized?

Yes, crane rails can be customized to meet specific project requirements. Customization options may include rail profiles, dimensions, material grades, and surface treatments. Working with a reputable rail supplier can help you tailor the rail solution to your unique needs.

7. How important is maintenance for crane rails?

Proper maintenance is essential for crane rails to ensure optimal performance, safety, and longevity. Regular inspections, lubrication, and timely repairs or replacements of worn-out components are crucial to keep the rail system in top condition. Following manufacturer guidelines and industry best practices can help extend the lifespan of crane rails.

8. How can I choose the right crane rail supplier?

Choosing the right crane rail supplier is vital for obtaining high-quality products and reliable support. Consider factors such as supplier reputation, experience, product quality, customization capabilities, customer reviews, and after-sales service. Requesting references and evaluating their track record can help you make an informed decision.

For any further questions or inquiries regarding crane rails, feel free to reach out to our experts. We are dedicated to providing comprehensive solutions and exceptional customer service.

At YONGYANG, we take pride in delivering high-quality rail solutions that meet and exceed industry standards. Our commitment to excellence ensures that every Qu80 Rail we produce undergoes rigorous quality checks and adheres to the strictest specifications.

By choosing the Qu80 Rail, you can expect enhanced operational efficiency, reduced downtime, and increased productivity. Its superior strength and reliability will streamline your material handling processes, allowing you to meet project deadlines and surpass customer expectations.

Partner with us to experience the power of the Qu80 Rail in your heavy-duty operations. Contact us today to discuss your specific requirements and discover how our top-of-the-line rail solution can optimize your industrial processes, ensuring success and longevity for your business.

Leave a message