发布时间:2020/9/6 17:47:34

近日,河北永洋特钢集团有限公司投建的具有自主知识产权的世界首套、国内首推全自动轻轨万能连轧生产线顺利过钢,试车成功,经检验产品通条断面尺寸和表面质量全部合格,轧机性能指标和全自动轧钢控制系统表现稳定,连续生产30余根合格产品。

该自动化轻轨万能连轧生产线创新性的采用了“2+7”轻轨半连轧工艺路线,实现了轻轨的长尺智能化预弯、长尺冷却及长尺矫直、在线自动化精整,开创了轻轨生产的全新生产工艺模式;同时配备了国内首套智能轻轨长尺冷床,采用了自主研发的长尺轻轨智能预弯技术、风冷和水雾冷却双强冷技术、智能取钢技术等先进技术,在成材率、综合作业率、吨钢耗电、人均钢产量以及质量改善和环保提升等方面,均达到了国内领先水平。

近年来,河北永洋特钢集团有限公司利用研发中心和建设创新中心技术平台,加强与钢铁研究总院、北京科技大学等科研院所合作,提升产品研发能力,持续开发了汽车用钢、高强度紧固件用钢、桥梁用钢、石油开采用钢、超临界和超超临界高压锅炉管坯等高质量高附加值特殊钢产品,着力打造国内精品轨道钢和精品优特钢生产基地。

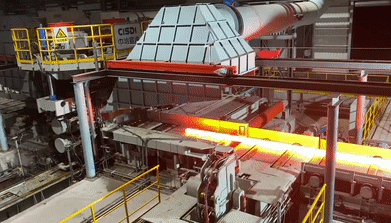

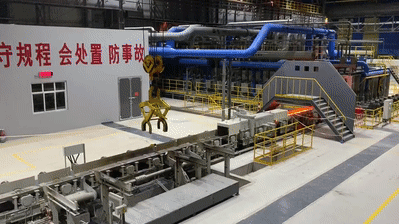

此次试车成功的全自动化轻轨万能连轧生产线定位于轻轨、电梯轨、工业道轨和矿用工字钢等特种型钢产品的生产应用,核心技术采用了具有国内完全自主知识产权的中冶赛迪加工制造的2架BDCD开坯轧机和7架UMCD万能轧机。该万能轧机采用了高刚度牌坊式结构和先进的TCS工艺控制系统,首次将自动辊缝控制(AGC)与液压位置控制(HPC)集成到一起,把智慧化高精度万能型钢轧机应用于型钢连轧生产线,实现高效生产高精度轻轨、H型钢、矿用型钢等产品。该项技术颠覆了传统横列式型钢生产线落后工艺,并解决了短应力线式万能轧机固定辊缝轧制法的工艺缺陷,实现了特种型钢生产的孔型与微张力自适应控制,提高了轧制的过程自动化与智能化水平,提升了产品综合质量与生产效率。

河北永洋特钢集团全自动化轻轨万能轧机生产线的顺利投产,实现了闭口牌坊式型钢万能轧机装备自主化的突破,打破从同类核心工艺及装备技术长期依赖进口的局面,提升了钢铁服务高端制造业的水平,强有力的推动了中国轨道用钢生产工艺及装备技术迈向世界领先水平。

THE FIRST LIGHT RAIL UNIVERSAL CONTINUOUS ROLLING PRODUCTION LINE INVESTED AND BUILT BY YONGYANG SPECIAL STEEL HAS BEEN SUCCESSFULLY TESTED

Released on: September 6, 2020 17:47:34

Recently, the world's first fully automatic light rail universal continuous rolling production line with independent intellectual property rights invested and built by Hebei Yongyang Special Steel Group Co., Ltd., the first in China, passed the steel smoothly, and the test run was successful. After the inspection, the product section size and surface quality were all qualified. The performance index of the mill and the fully automatic steel rolling control system were stable, and more than 30 qualified products were continuously produced.

The automatic light rail universal continuous rolling production line innovatively adopts the "2+7" light rail semi continuous rolling process route, realizes the intelligent pre bending, cooling, straightening and online automatic finishing of light rail, and creates a new production process mode of light rail production; At the same time, it is equipped with the first intelligent light rail long cooling bed in China, and has adopted the self-developed intelligent pre bending technology of long light rail, air cooling and water mist cooling double strong cooling technology, intelligent steel tapping technology and other advanced technologies. It has reached the domestic leading level in terms of yield, comprehensive operation rate, power consumption per ton of steel, per capita steel output, quality improvement and environmental protection improvement.

In recent years, Hebei Yongyang Special Steel Group Co., Ltd. has made use of the technology platform of the R&D center and the construction innovation center to strengthen cooperation with the General Institute of Iron and Steel Research, Beijing University of Science and Technology and other scientific research institutes, improve the product R&D capability, and continuously developed high-quality and high added value special steel products such as automobile steel, high-strength fastener steel, bridge steel, oil mining steel, supercritical and ultra supercritical high pressure boiler billets, Strive to build a domestic production base for high-quality rail steel and high-quality special steel.

The successful full-automatic light rail universal continuous rolling production line in this trial run is positioned in the production and application of special section steel products such as light rail, elevator rail, industrial track and mining I-beam. The core technology adopts two BDCD bloom rolling mills and seven UMCD universal rolling mills processed and manufactured by MCC CCID with full independent intellectual property rights in China. The universal mill adopts a high rigidity arch structure and advanced TCS process control system. It integrates automatic gap control (AGC) and hydraulic position control (HPC) for the first time, applies intelligent high-precision universal section mill to the continuous section rolling production line, and realizes the efficient production of high-precision light rail, H-beam, mining section steel and other products. This technology subverts the backward process of the traditional horizontal section steel production line, solves the process defects of the fixed roll gap rolling method of the short stress line universal mill, realizes the adaptive control of pass and micro tension in the production of special section steel, improves the automation and intelligent level of the rolling process, and improves the comprehensive quality and production efficiency of the product.

High pressure water phosphorus removal

BD2 rolling mill steel

Passing steel by universal continuous rolling mill

The smooth operation of the fully automated light rail universal rolling mill production line of Hebei Yongyang Special Steel Group has achieved a breakthrough in the localization of the closed arch type universal rolling mill equipment, broken the situation of long-term dependence on imports from similar core processes and equipment technologies, improved the level of steel services for high-end manufacturing, and strongly promoted China's rail steel production process and equipment technology to the world's leading level.

Finished products

Leave a message